Pulse-Jet

Pulse-Jet

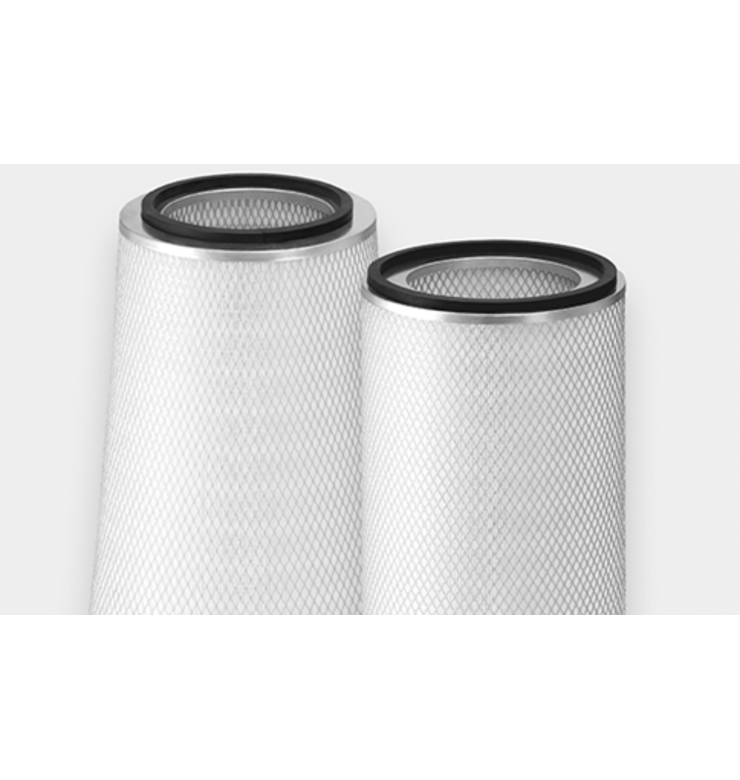

GTS10

Filtration for Pulse-jet Systems

The GTS10 premium filtration series is used in both onshore and offshore applications. Maximized with their self-cleaning characteristics, these filters increase the lifetime of intake air systems while reducing operating cost.

Applications Features

| Item Description | Version | Construction height [in] | Outer diameter [in] | Rated Air Flow [cfm] | Initial pressure drop [in w.g.] |

Filter class acc. to ISO 29461-1 |

Filter class acc. to EN 1822 | |

|---|---|---|---|---|---|---|---|---|

| GTS10 324W | Cylindrical | 26 | 12.8 | 650 | 0.52 | ISO T10 | E10 | |

| GTS10 445K | Conical | 26 | 17.8 | 820 | ISO T10 | E10 | ||

| GTS10 324-445W Set | Set | 52 | 12.8 / 17.8 | 1.470 | 0.58 | ISO T10 | E10 |

Applications

Pulse-jet filter cartridges of GTS10 series are used for intake air filtration of gas turbines and turbo compressors at both onshore and offshore installations. They are particularly suitable for locations with critical on-site conditions like desert areas or tropical climates with high relative humidity.

Features

GTS10 pulse-jet filter cartridges, with their optimized self-cleaning characteristics, maximize the lifetimes of intake air systems for turbomachinery and reduce the operating costs significantly.

Innovative high-performance nonwovens with a water repellent finish and made of synthetic microfibers enable the GTS10 series to retain their excellent performance features under most extreme climatic conditions.

The filter medium achieves high arrestance performance, large dust holding capacity, a low average pressure drop and high cost-efficiency.

GTS10 filter cartridges have been optimized in terms of filtering area and pleat geometry. The active filtering area remains effective over the entire operational lifetime.

In order to avoid corrosion, the inner and outer support cages, plus the cover and base, are made from galvanized steel or stainless steel. These components are cast in a leakproof configuration, so as to ensure maximized security against dust breakthrough during pulse-jet cleaning.