Pulse-jet filter cartridges

Pulse-jet filter cartridges

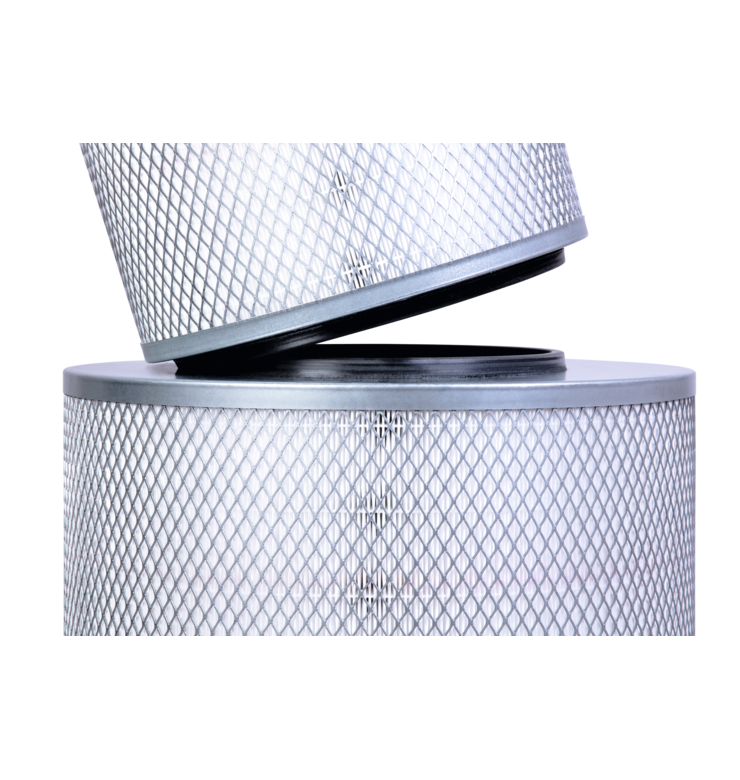

GTS double-cylindrical

Applications Features

| Article | Article number | Class to ISO 16890 | Filter class acc. to EN 1822 | Filter class acc. to ISO 29461-1 | Filter class acc. to EN 779:2012 |

Nominal volume flow [m³/h] |

Initial pressure drop [Pa] | MPPS efficiency [%] 1 | Construction height [mm] | Filter class acc. to ASHRAE 52.2:2017 | Outer diameter [mm] | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GTS9 324A/324C/660-GGG-25P45-BBA | 53573362 | ISO ePM1 75% | ISO T8 | F9 | 1,100 | 130 | 660 | MERV14 | 324 | |||

| GTS9 445A/445E/660-GGG-38P45-BBA | 73094405 | ISO ePM1 75% | ISO T8 | F9 | 1,400 | - | 660 | MERV14 | 445 | |||

| GTS9 324-445 Set (Double -Cylindrical) | - | ISO ePM1 75% | ISO T8 | F9 | 2,500 | 115 | 1,330 | MERV14 | 445 / 324 | |||

| GTS9+ 324A/324C/660-GGG-25Q45-BBA | 73094414 | ISO ePM1 85% | ISO T9 | F9 | 1,100 | 135 | 660 | MERV15 | 324 | |||

| GTS9+ 445A/445E/660-GGG-38Q45-BBA | 73094413 | ISO ePM1 85% | ISO T9 | F9 | 1,400 | 800 | 660 | MERV15 | 445 | |||

| GTS9+ 324-445 Set (Double-Cylindrical) | ISO ePM1 85% | ISO T9 | F9 | 2,500 | 120 | 1,330 | MERV15 | 445 / 324 | ||||

| GTS10 324A/324C/660-GGG-26R45-BBA | 73094407 | ISO ePM1 >95% | E10 | ISO T10 | 1,100 | 150 | 89 | 660 | MERV16 | 324 | ||

| GTS10 445A/445E/660-GGG-32R45-BBA | 73094423 | ISO ePM1 >95% | E10 | ISO T10 | 1,400 | 89 | 660 | MERV16 | 445 | |||

| GTS10 324-445 Set (Double-Cylindrical) | ISO ePM1 >95% | E10 | ISO T10 | 2,500 | 140 | 89 | 1,330 | MERV16 | 445 / 324 |

Applications

Pulse-jet filter cartridges of GTS double-cylindrical series are used for intake air filtration of gas turbines and turbo compressors at both onshore and offshore installations. They are particularly suitable for locations with critical on-site conditions like desert areas or tropical climates with high relative humidity.

Features

GTS pulse-jet filter cartridges in double-cylindrical design, with their optimized self-cleaning characteristics, maximize useful lifetimes and minimize particle ingress in turbomachinery systems.

High-strength synthetic microfiber nonwovens with water-repellent coating enable the GTS series to maintain excellent operational characteristics in all climatic duty conditions including high humidity locations.

The double-cylindrical geometry in combination with flow-optimized spacing results in a particularly low pressure drop and very good cleanability via pulse-jet. This better pulse ability is a result of more open pleats compared to conical-cylindrical geometries.

Innovative packaging of cartridge pairs reduces the transport volumes and packaging material. This makes an important contribution to sustainable environmental protection.

To minimize corrosion and handling damage, the inner and outer support cage and base end caps are made from galvanized steel or stainless steel.

Overview of the GTS double-cylindrical filter cartridges

Double-cylindrical pulse-jet filter cartridges GTS

Particles in the intake air of gas turbines increase the risk of damage and can impair performance. Effective protection against dust is therefore essential for gas turbines. Multi-stage filtration systems extend the life of the turbine and increase its efficiency. The probability of dust-related damage decreases. At locations with critical conditions such as high humidity, Pulse-jet filter cartridges of the double-cylinder GTS series are used.

Areas of application for GTS

Double-cylindrical GTS pulse-jet filter cartridges from Viledon are suitable for intake air filtration of gas turbines and turbo-compressors. They ensure maximum air purity onshore and offshore. The GTS Pulse-jet filter cartridges are mainly used in locations with critical conditions, for example in tropical or desert regions.

GTS Pulse-jet filter cartridges and their advantages

The double-cylindrical geometry, together with the optimal pleat spacing, results in a particularly low pressure difference and very good cleaning behaviour using pulse-jet. As a result, GTS pulse-jet filter cartridges maximise the lifetime of intake air systems for turbomachinery and minimise the ingress of particles. Thanks to water-repellent high-performance nonwovens, the excellent performance of the series is maintained under all climatic conditions. The cover and base are made of galvanised steel or stainless steel to prevent corrosion and damage during handling.