Cassette Filters

Cassette Filters

MaxiPleat

Quality for Extreme Conditions

With a hydrophobic coating, a thermal embossing process, and leak-proof casting, the MaxiPleat series offers continuous reliable operation for even the most extreme conditions.

Applications Features

Downloads

| Item Description | Nominal dimensions (W x H x D) [in] | Filter area [ft2] | Rated Air Flow [cfm] | Initial pressure drop [in w.g.] | Class to ISO 16890 | ASHRAE 52.2 Efficiency |

Filter class acc. to ISO 29461-1 |

Filter class acc. to EN 1822 | |

|---|---|---|---|---|---|---|---|---|---|

| MX75 | 24 x 24 x 12 | 194 | 2.500 | 0.54 | ePM10 85% | ISO T5 | |||

| MX85 | 24 x 24 x 12 | 194 | 2.500 | 0.56 | ePM2.5 65% | ISO T6 | |||

| MX95 1/1 | 24 x 24 x 12 | 194 | 1.970 | 0.37 | ePM1 75% | MERV 14 | ISO T7 | ||

| MX95 5/6 | 20 x 24 x 12 | 156 | 1.640 | 0.37 | ePM1 75% | MERV 14 | ISO T7 | ||

| MX95 1/2 | 12 x 24 x 12 | 81 | 985 | 0.37 | ePM1 75% | MERV 14 | ISO T7 | ||

| MX98 1/1 | 24 x 24 x 12 | 194 | 1.970 | 0.44 | ePM1 85% | MERV 15 | ISO T9 | ||

| MX98 5/6 | 20 x 24 x 12 | 156 | 1.640 | 0.44 | ePM1 85% | MERV 15 | ISO T9 | ||

| MX98 1/2 | 12 x 24 x 12 | 81 | 985 | 0.44 | ePM1 85% | MERV 15 | ISO T9 | ||

| MXH10 1/1 | 24 x 24 x 12 | 194 | 2.500 | 1.00 | ePM1 95% | MERV 16 | ISO T10 | E10 | |

| MX100 1/1 | 24 x 24 x 12 | 194 | 2.000 | 0.81 | ePM1 >95% | MERV 16 | ISO T11 | E11 | |

| MX100 5/6 | 20 x 24 x 12 | 156 | 1.600 | 0.81 | MERV 16 | ISO T11 | E11 | ||

| MX100 1/2 | 12 x 24 x 12 | 81 | 900 | 0.81 | MERV 16 | ISO T11 | E11 | ||

| MX120 1/1 | 24 x 24 x 12 | 248 | 2.000 | 1.37 | ISO T12 | E12 | |||

| MX120 5/6 | 20 x 24 x 12 | 205 | 1.600 | 1.37 | ISO T12 | E12 | |||

| MX120 1/2 | 12 x 24 x 12 | 118 | 900 | 1.37 | ISO T12 | E12 |

Applications

Viledon MaxiPleat cassette filters offer maximized operational reliability and cost-efficiency for supply, exhaust and recirculated air filtration in ventilation systems in:

- Intake air filtration for gas turbines and compressors

- Industrial processes (chemicals, pharmaceuticals, foods and beverages, optics, electronics, surface treatment, etc.)

- Sophisticated air-conditioning applications (laboratories, libraries, museums, airports, office buildings, etc.)

Features

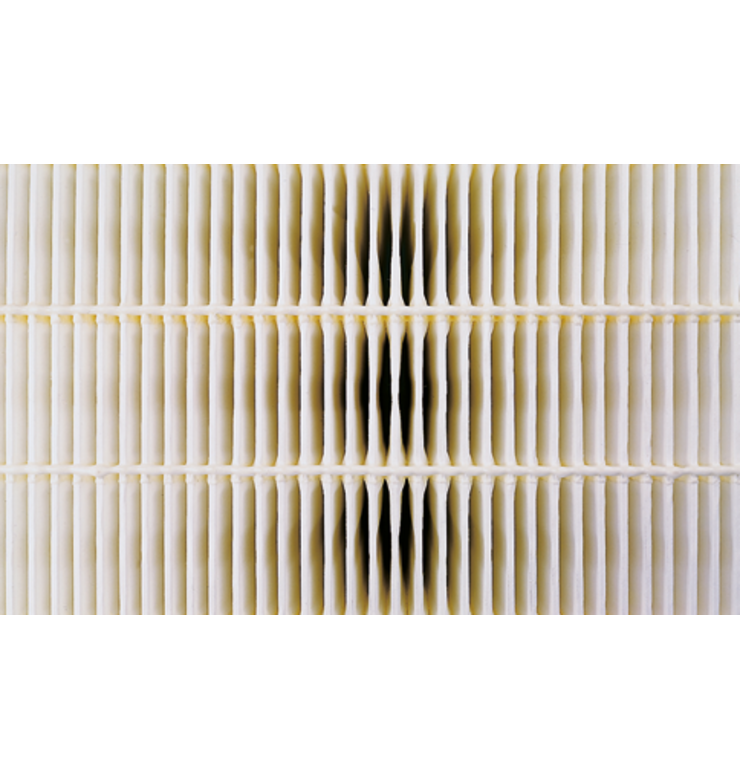

Our thermal embossing process, with its optimum V-shaped maximum pleated depth media ensures full utilization of the filtering area and uniform dust deposition.

High-strength micro-glassfiber papers with a special thermoplastic bonding system and hydrophobic coating are used as filter media.

The low average pressure drop ensures a long useful lifetime, with cost-efficient and reliable operation.

The leak-proof casting of the dimensionally stable pleat pack in the distortion-resistant plastic frame results in outstanding bursting strength as well as high security against dust penetration.

Overview of the MaxiPleat cassette filters

Cassette filter MaxiPleat

Cassette filters (together with filter mats, pocket filters and HEPA filters) belong to the group of depth-loading filters. Their filter media are used in pleated (folded) form to achieve the largest possible filter media area. The stable construction of MaxiPleat cassette filters from Viledon provides continuous reliable operation, even under extreme conditions.

Application areas of MaxiPleat

The MaxiPleat cassette filters are used for supply, exhaust and recirculation filtration of air conditioning systems, for example in the intake air filtration of gas turbines and compressors. They are suitable for industrial processes such as pharmaceuticals, the food industry or electronics. MaxiPleat cassette filters are also used in sophisticated air conditioning technology.

MaxiPleat cassette filters and their advantages

The extremely resilient MaxiPleat cassette filters enable maximum operational dependability. Thanks to homogeneous media velocity with a low average pressure drop, a long lifetime is achieved with economical and safe operation. The leak-proof casting of the dimensionally stable pleat pack in the distortion-resistant plastic frame ensures the exceptional sturdiness and prevents dust penetration.