171

Results

Filter products

Close filter

Active filters

171 Results

Product groups

Filter classes

APPLICATIONS

Products

Paint mist arrestors

Paint mist arrestors

Paint Pockets

Filter medium

100% synthetic

Paint mist arrestance efficiency

>99%

Paint mist arrestors

edrizzi Vario fine, medium and coarse

Filter medium

Corrugated cardboard

Paint mist arrestance efficiency

≤97%

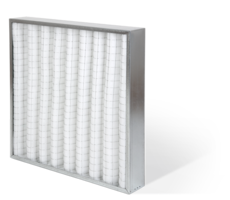

Filter cells

CPack C

ISO 16890

ISO coarse